Globe valves for high-temperature mediums

PURPOSE AND SCOPE

They are used as locking and locking-controlling arms of flow and fluid operating mediums: water, industrial water, steam, technological gases (oxygen, hydrogen, hydrogen sulfide, coke, domain), plant and technical oils, paraffin, oil products, carbohydrates, diesel fuel, kerosene, petrol, coking oil products at the temperature up to 450°С.

ADVANTAGES AND DETAILS OF CONSTRUCTION:

- unique technique of fitting and bedding of plug and seat spherical surfaces provides getting of class A hermiticity for metal-to-metal seal;

- a spring load construction of metal seat provides its hermiticity both at large and at small dimensions of operating pressure at differential temperature of operating pressure during the whole period of operation, and also prevents details jamming in the thermal expansion of valve details with the temperature of operating mediums up to 450°С;

- seat performance metal-to-metal allows using of globe valves both in locking and regular regime;

- globe valves have full-bore construction that minimizes hydraulic losses in pipeline and prevents runout of valve operating surface;

- valves are made in versions with manual (mechanical) drive, with pneumatic and electric drive.

TECHNICAL FEATURES

| Hermiticity class according to the GOST 9544 | Class A | |

| Climate version according to the GOST 15150-69 | U1 - moderate (surrounding temperature from -45°С to +50°С) HL1 - cold (surrounding temperature from -60°С to +40°С) |

|

| Operating medium | For material version - C | Overheated steam, water, industrial water, technological gases (oxygen, hydrogen), plant and technical oils, paraffin, oil products, carbohydrates, diesel fuel, kerosene, petrol, coking oil products at the temperature up to 425°С. |

| For material version - H or M | solutions of alkalis, acids, paint products, technological gases (blast-furnace, coke, gases containing hydrogen sulfide, sulfur and hydrogen) and other aggressive flow and fluid operating mediums at the temperature up to 450°C. | |

MATERIAL VERSION*

| Part name | Material depending on the type | ||

| C | H | M | |

| Body | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Fluid cap | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Globe | Steel 30X13 | Steel 12X18H10T+Xtv30 | Steel 10X17H13M2T+Xtv30 |

| Seat | Special iron, special bronze | ||

| Spindle | Steel 30X13 | Steel 12X18H10T | Steel 10X17H13M2T |

| Oil-seal housing | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Sealing material | Graflex | ||

*The manufacturing of globe valves of others corrosion-resistant steel is possible by individual order.

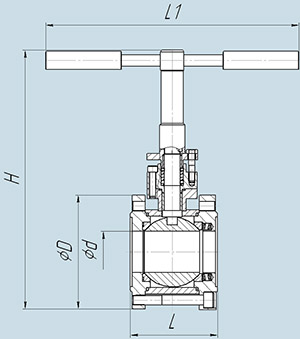

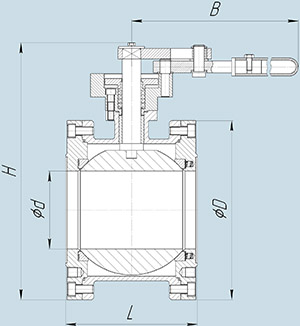

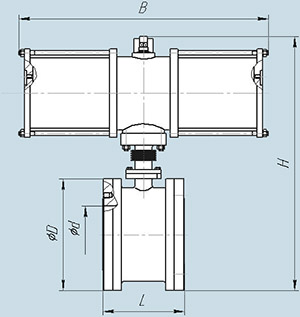

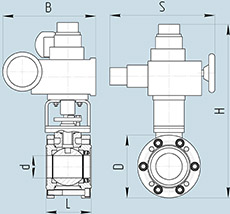

Main dimensions and drawings

|

|

| Valve with manual drive (DN<150mm) | Valve with "broken lever" (DN>=150mm) |

|

|

| Valve with pneumatic drive | Valve with electric drive |

Basic globe valve versions. Scheme of conventional symbols

| Valve model | Diameter DN, mm | Nominal pressure PN, MPa (kgf/cm2) | Material | Drive type | Connection to the pipeline | Climatic version | Overall dimentions mm | Weight, kg | |||||

| L | H | D | B | S | d | ||||||||

| T | 15 | 0,6 (6) 1,0 (10) 1,6 (16) 2,5 (25) 4,0 (40) |

С Н М |

R | for welding (on request flanged) | U1 HL1 |

75 | 270 | 90 | 250 | - | 14 | 4,2 |

| P | 300 | 315 | - | 14,5 | |||||||||

| E | 340 | 185 | 245 | 11,2 | |||||||||

| 20 | R | 78 | 280 | 100 | 200 | - | 20 | 6,4 | |||||

| P | 315 | 315 | - | 15,8 | |||||||||

| E | 350 | 185 | 245 | 14,2 | |||||||||

| 25 | R | 80 | 345 | 115 | 200 | - | 25 | 7,8 | |||||

| P | 345 | 315 | - | 18,0 | |||||||||

| E | 375 | 185 | 245 | 15,8 | |||||||||

| 32 | R | 92 | 350 | 140 | 300 | - | 31 | 10,0 | |||||

| P | 360 | 315 | - | 20,0 | |||||||||

| E | 410 | 185 | 245 | 18,0 | |||||||||

| 40 | R | 112 | 345 | 145 | 300 | - | 39 | 12,0 | |||||

| P | 385 | 315 | - | 24,8 | |||||||||

| E | 420 | 185 | 245 | 20,0 | |||||||||

| 50 | R | 120 | 220 | 150 | 300 | - | 50 | 15,8 | |||||

| P | 415 | 315 | - | 31,0 | |||||||||

| E | 430 | 185 | 245 | 23,8 | |||||||||

| 65 | R | 138 | 355 | 180 | 350 | - | 65 | 19,2 | |||||

| P | 475 | 560 | - | 36,0 | |||||||||

| E | 620 | 300 | 450 | 47,2 | |||||||||

| 80 | R | 145 | 360 | 195 | 400 | - | 72 | 22,6 | |||||

| P | 525 | 560 | - | 47,0 | |||||||||

| E | 645 | 300 | 450 | 50,6 | |||||||||

| 100 | R | 170 | 410 | 215 | 400 | - | 90 | 35,0 | |||||

| P | 565 | 560 | - | 59,0 | |||||||||

| E | 675 | 300 | 450 | 63,0 | |||||||||

| 125 | R | 215 | 377 | 268 | 400 | - | 120 | 47,0 | |||||

| P | 630 | 670 | - | 89,0 | |||||||||

| E | 855 | 402 | 472 | 114,0 | |||||||||

| 150 | R | 260 | 475 | 345 | 500 | - | 150 | 72,0 | |||||

| P | 855 | 670 | - | 172,0 | |||||||||

| E | 940 | 402 | 472 | 139,0 | |||||||||

| 200 | R | 300 | 510 | 418 | 500 | - | 200 | 96,0 | |||||

| P | 980 | 690 | - | 210,0 | |||||||||

| E | 1035 | 467 | 472 | 220,0 | |||||||||

Note:

A globe valve completing is possible with pneumatic drive and optional modules:

PR – pneumatic valve (24;110;220 В); FR – filter-regulator; RD – manual override,

KBS – quick release valve; SKP – limit switch;

KMCh (installation kit): mating flanges, fittings, blotters

Example of designation:

Interflanged globe valve of mark T with dimensional number DN150 and nominal pressure PN 2,5 MPa, valve material – hand-powered carbon steel of climate version U1, on the operating medium - overheated steam up to 425°С:

Globe valve Т-150-025-C-R (interflanged, U1, overheated steam 425°С) TU U 29.1-35907383-001:2008

Notice:

1. Connection types, climate version, peculiarities of operating medium, requirements on completing of pneumatic and electric drives are indicated within brackets after the basic reference of globe valve.

2. Basic configuration of globe valve with electric drive includes electric drive electric flange actuators of general purpose industrial version (production «ABS Automation», Cheboksary city);

3. Basic configuration of globe valve with pneumatic drive includes double-acting link-motion drive of mark PK, of domestic manufacture.

4. To order valves with parameters which are different from ones shown in the table please fill in check list and send to us, so we can confirm our ability to meet your requirements.