Standard version of globe valve for liquid and gas

|

|

|

|

with manual drive |

with electric drive |

PURPOSE AND SCOPE

Valves are used as locking arms in the processing lines on the operating mediums: water, gas (natural gas, propane, butane), air, black oil fuel, plant and technical oils, oil products, diesel fuel, kerosene, petrol, at the temperature up to 200°С.

ADVANTAGES AND DETAILS OF CONSTRUCTION:

- globe valves have full-bore construction and are made in the version with manual (mechanical) drive, pneumatic and electric drive;

- valve construction is modular, it consists of one-piece body and two joints connected with body by stud bolts that provides its maintainability;

- using of “broken lever” on the manual drive(for DN150, DN200 and higher) allows halve torque at "opening-closing" of the valve;

plug (globe) is made of corrosion-resistant steels (30X13, 12X18H10T, 10X17H13M2T).

Technical Characteristics

| Hermiticity class according to GOST9544 | Class A | |

| Climatic version according to GOST 15150-69 | U1 - moderate (surrounding temperature from -45ºС to +50ºС)HL1 - cold (surrounding temperature from -60ºС to +40ºС) | |

| Type of control | R - manual (mechanical) drive;P - pneumatic drive;E - electric drive. | |

| Joining to pipeline | Flanged according to GOST12815-80 | |

| Total average service life | No less than 8 000 cycles | |

| Total average life | No less than 1 500 cycles | |

| Operating medium | For material version - C | water, air, oil, vegetable oils and industrial oils, petroleum, diesel, kerosene, petrol |

| For material version – Н or М | corrosive fluids (acids and alkalis), gases containing aggressive impurities (hydrogen, oxygen, sulfur, hydrogen sulfide, etc.), etc. | |

| Manufacture | Serial according to TU U 29.1-35907383-001:2008 | |

Material category*

| Main parts | Material | ||

| C | H | M | |

| Body | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Flange | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Ball | Steel 30X13 | Steel 12X18H10T | Steel 10X17H13M2T |

| Seat | fluoroplastic F-4 | ||

| Spindle | Steel 30X13 | Steel 12X18H10T | Steel 10X17H13M2T |

| Packing box | Steel 20 | Steel 12X18H10T | Steel 10X17H13M2T |

| Sealing | fluoroplastic F-4 | ||

*By individual order it is possible to manufacture globe valves of other corrosion-resisting steel

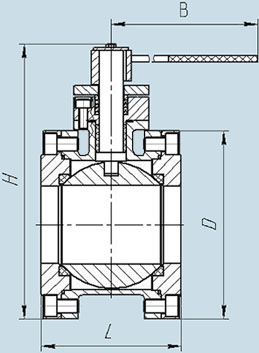

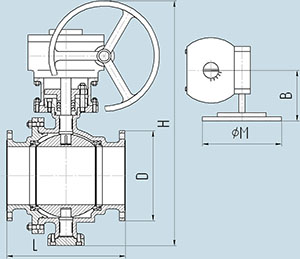

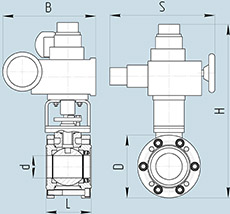

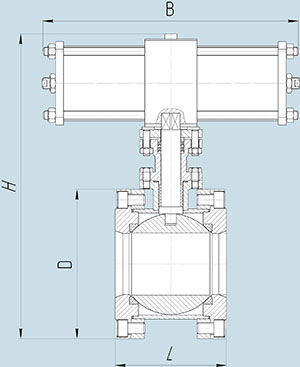

Main dimensions and drawings

|

|

| Valve with manual drive (DN<200mm) | Valve with manual mechanical drive (DN >=200mm) |

|

|

| Valve with electric drive | Valve with electric drive |

Basic globe valve versions. Scheme of conventional symbols

| Valve model | Diameter DN, mm | Nominal pressure PN, MPa (kgf/cm2) | Material | Drive type | Connection to the pipeline | Climatic version | Overall dimentions mm | Weight, kg | |||||

| L | Н | D | B | S | M | ||||||||

| S | 15 | 0,6(6) 1,0(10) 1,6(16) 2,5(25) 4,0(40) |

С Н М |

R | Interflanged | U1 HL1 |

70 | 270 | 90 | 150 | - | - | 3,5 |

| 15 | P | 70 | 270 | 90 | 315 | - | - | 13,0 | |||||

| 15 | E | 70 | 470 | 90 | 560 | 245 | - | 9,5 | |||||

| 20 | R | 75 | 270 | 100 | 200 | - | - | 5,3 | |||||

| 20 | P | 75 | 270 | 100 | 315 | - | - | 17,0 | |||||

| 20 | E | 75 | 480 | 100 | 560 | 245 | - | 11,0 | |||||

| 25 | R | 75 | 280 | 115 | 200 | - | - | 7,2 | |||||

| 25 | P | 75 | 270 | 115 | 315 | - | - | 21,0 | |||||

| 25 | E | 75 | 480 | 115 | 605 | 245 | - | 12,8 | |||||

| 32 | R | 90 | 345 | 140 | 300 | - | - | 9,5 | |||||

| 32 | P | 90 | 305 | 140 | 315 | - | - | 22,0 | |||||

| 32 | E | 90 | 545 | 140 | 670 | 245 | - | 14,8 | |||||

| 40 | R | 105 | 345 | 145 | 300 | - | - | 11,0 | |||||

| 40 | P | 105 | 305 | 145 | 315 | - | - | 23,5 | |||||

| 40 | E | 105 | 545 | 145 | 670 | 245 | - | 16,0 | |||||

| 50 | R | 120 | 220 | 150 | 300 | - | - | 14,6 | |||||

| 50 | P | 120 | 350 | 150 | 315 | - | - | 37,8 | |||||

| 50 | E | 120 | 420 | 150 | 1350 | 245 | - | 17,0 | |||||

| 65 | R | 135 | 355 | 180 | 350 | - | - | 18,3 | |||||

| 65 | P | 135 | 380 | 180 | 560 | - | - | 65,0 | |||||

| 65 | E | 135 | 555 | 180 | 1350 | 245 | - | 22,5 | |||||

| 80 | R | 140 | 360 | 195 | 400 | - | - | 21,6 | |||||

| 80 | P | 140 | 380 | 195 | 560 | - | - | 65,0 | |||||

| 80 | E | 140 | 560 | 195 | 1350 | 450 | - | 47,6 | |||||

| 100 | R | Flanged | 170 | 410 | 215 | 400 | - | - | 35,0 | ||||

| 100 | P | 170 | 430 | 215 | 560 | - | - | 73,3 | |||||

| 100 | E | 170 | 710 | 215 | 1350 | 450 | - | 61,0 | |||||

| 125 | R | 210 | 377 | 268 | 400 | - | - | 54,0 | |||||

| 125 | P | 210 | 620 | 268 | 670 | - | - | 120,0 | |||||

| 125 | E | 210 | 677 | 268 | 1350 | 450 | - | 80,0 | |||||

| 150 | R | 260 | 475 | 345 | 500 | - | - | 68,0 | |||||

| 150 | P | 260 | 810 | 345 | 670 | - | - | 198,0 | |||||

| 150 | E | 260 | 875 | 345 | 1850 | 472 | - | 135,0 | |||||

| 200 | R | 290 | 510 | 418 | 500 | - | - | 90,0 | |||||

| 200 | P | 290 | 860 | 418 | 690 | - | - | 246,0 | |||||

| 200 | E | 290 | 910 | 418 | 1850 | 472 | - | 157,0 | |||||

| 250 | R | 533 | 985 | 445 | 380 | - | 450 | 258,0 | |||||

| 300 | R | 610 | 1104 | 510 | 380 | - | 500 | 390,0 | |||||

| 350 | R | 686 | 1265 | 570 | 380 | - | 500 | 510,0 | |||||

| 400 | R | 762 | 1400 | 655 | 380 | - | 500 | 750,0 | |||||

| 450 | R | 864 | 1485 | 680 | 380 | - | 500 | 960,0 | |||||

| 500 | R | 914 | 1580 | 755 | 380 | - | 550 | 1190,0 | |||||

Example of conventional symbol at the time of order

Valve interflanged model S with nominal diameter DN65 and nominal pressure PN2,5MPa, valve material carbon steel, climatic version U1, manual drive, operating medium - residual fuel.

Valve S-065-025-С-R (interflanged, U1, residual fuel) TU U 29.1-35907383-001:2008

Notes:

- Joining type, climatic version, requirements for compliment of pneumatic and electric drives, peculiarities of operating medium are named in brackets after main description of a valve.

- Basic configuration of globe valve with electric drive includes electric drive electric flange actuators of general purpose industrial version (production «ABS Automation», Cheboksary city);

- Basic configuration of globe valve with pneumatic drive includes double-acting link-motion drive of mark PK, of domestic manufacture.

- To order valves with parameters which are different from ones shown in the table please fill in check list and send to us, so we can confirm our ability to meet your requirements.